User manual

The fuel meter is designed to measure the flow of liquid fuel in the engines of cars, river vessels, diesel generators, as well as in boilers, burners and other equipment where fuel is used. The performance of the devices must be ensured when high-quality diesel and motor fuel flows through them.

[ Fuel meter. External view ]

Technical specifications

The technical characteristics of the fuel meter are given in the table below.

| Parameters | Values |

| Limits of permissible errors ± % ,is no more | 1 |

| Supply voltage, V | 12/24 |

| Power supply current, mA , is no more for U=12/24 V | 50/25 |

| Protection against impulse interference V, no less | 170 |

| Minimum/maximum fuel pressure, Mpa | 0,2/2,5 |

| Kinematic fuel viscosity min/max, mm2/s | 1,5/6,0 |

| The size of foreign inclusions in the liquid, mm no more | 0,1 |

| The number of pulses per liter F2/F5 | 100/50 |

| Temperature range, C° | -25..+85 |

| Interface for configuration | RS485 |

| Data transfer interface | Impulse RS485 CAN |

| Minimum-Maximum flow in the measuring chamber, l/h: | |

| M2M F2 | 2-200 |

| M2M F5 | 10-500 |

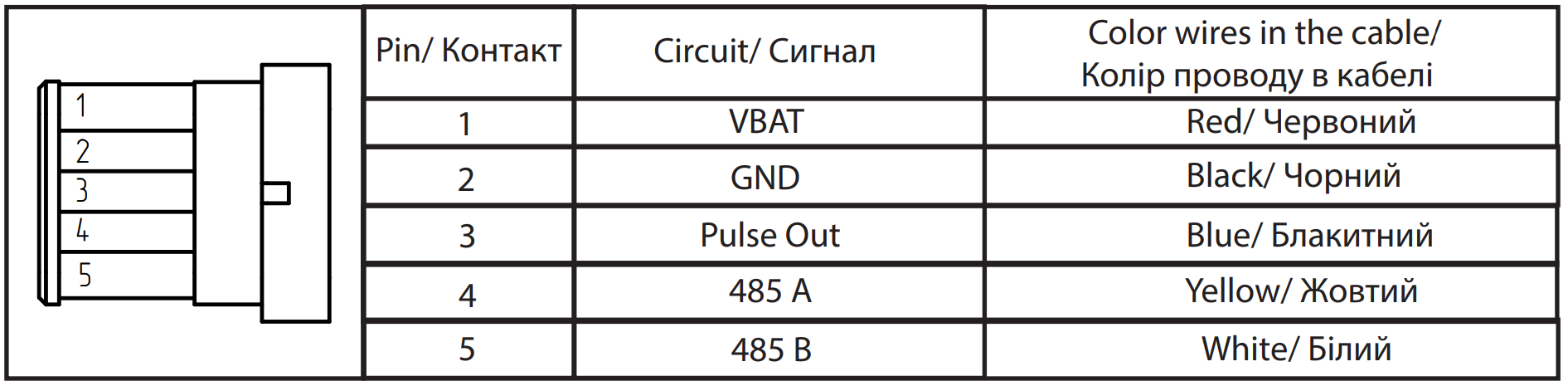

Connector contacts and wire color in the cable

The contact diagram is shown in the image below:

[ Contact diagram ]

External view of the contact connector is shown in the photo below:

[ External view of the contact connector ]

Indication and marking

The top cover of the meter has the following:

- Brand logo

- QR code for quick access to the manufacturer's website

- Product name and model (with maximum throughput)

- Serial number

Additionally, the direction of fuel flow is indicated by arrows:

[ Fuel direction ]

Red indicator indicates power availability.

[ Power indicator ]

A green indicator indicates that fuel is flowing through the device.

[ Fuel flow indicator ]

Delivery set

The delivery set includes:

- Fuel meter

- Passport

- Cable

Additional accessories

Additionally, the fuel meter can be equipped with:

- Cable of various lengths

- Mounting kit

- Filters

[ Fuel meter accessories ]

Maintenance

Maintenance of the meter is carried out by the personnel of the manufacturer or service center. The scope of maintenance work is determined by the maintenance specialist after checking the technical condition of the meter. For work related to cleaning of internal surfaces, repair or replacement of parts, repair or replacement of electronic components, calibration of the meter, it is transferred to the service center or the manufacturer's enterprise. For the duration of such maintenance, another meter or insert fitting is installed (upon agreement).

Maintenance is carried out after installation of the meter and periodically. Periodic maintenance is recommended every 12 months or 100 000 liters for the M2M F2 or 200 000 liters for the M2M F5. The frequency of maintenance may vary depending on the quality of the fuel, the condition of the filters, operating conditions, and the condition of the fuel system.

Safety instructions

Read all instructions carefully before use.

When working on auto-tractor machinery, safety rules must be followed when working with fuel liquids. When installing the meter, you must follow the safety rules adopted at yourcompany.

It is forbidden to turn on the meter at a voltage higher than the range specified in this document. When welding is done, it is necessary to unlock it from the power supply and disconnect the connector.

Warranty and service

The warranty period is 12 months from the date of sale by the manufacturer. Service is carried out only in service centers.

Utilization

M2M F2/F5 does not contain harmful substances and components dangerous for health and the environment.

M2M F2/F5 does not contain precious materials subject to control.